A need for safety analyses

During the past few decades, the chemical industry has converted raw materials such as oil, natural gas, air, water, metals, and minerals into more than 70,000 products. Chemistry is the centre of everything we can see, smell, touch, and taste. Our local grocery, hardware, garden, and drug stores carry an impressive array of commonly used chemicals, such as detergents, adhesives, lubricants, fabrics, pesticides, pharmaceutical drugs, and a multitude of fabricated plastic items.

Obviously, the industrial processes required to transform those raw materials into speciality chemicals inherently carry some risks. Therefore, it is always necessary to perform safety analyses: ensuring safe production processes that do not pose an excessive threat to the surrounding population, environment or building and equipment structures.

Consequence and risk modelling

Consequence modelling is used to predict the consequence effects of a potential accidental release of a hazardous chemical. The main objective of consequence modelling is to determine how the resulting accident effects would impact people, the environment, and property.

These accident effects are determined by calculating their extent for different phenomena such as pool fires, jet fires, flash fires, vapour cloud explosions, fireballs, BLEVEs and toxic gas releases. Consequence modelling studies can be used to plan beforehand what prevention and mitigation measures must be implemented on-site. This will ensure that chances of having an accidental release are reduced while its consequences are minimized to an acceptable level.

The concept of risk, a quantified value that can be calculated through risk modelling, is used to quantify the impact of these loss of containment scenarios. In process safety, “risk” is often described as the probability of fatal injury due to the exposure of a release of a hazardous chemical substance. Depending on the focus of a risk study, which can be internal safety (on-site) or external safety (off-site), other criteria may be applied. Typical risk criteria will always contain a specific “chance of damage happening” evaluation which can reflect a predefined acceptance threshold.

Such threshold criteria may be based on the concept of ALARP (which translates to “As Low As Reasonably Practicable”) or ALARA (“As Low As Reasonably Achievable”). But what does “reasonably” mean? Fortunately, many countries have already established regulatory risk acceptance criteria, while all big chemical companies have also defined their own “internal safety” risk acceptance levels.

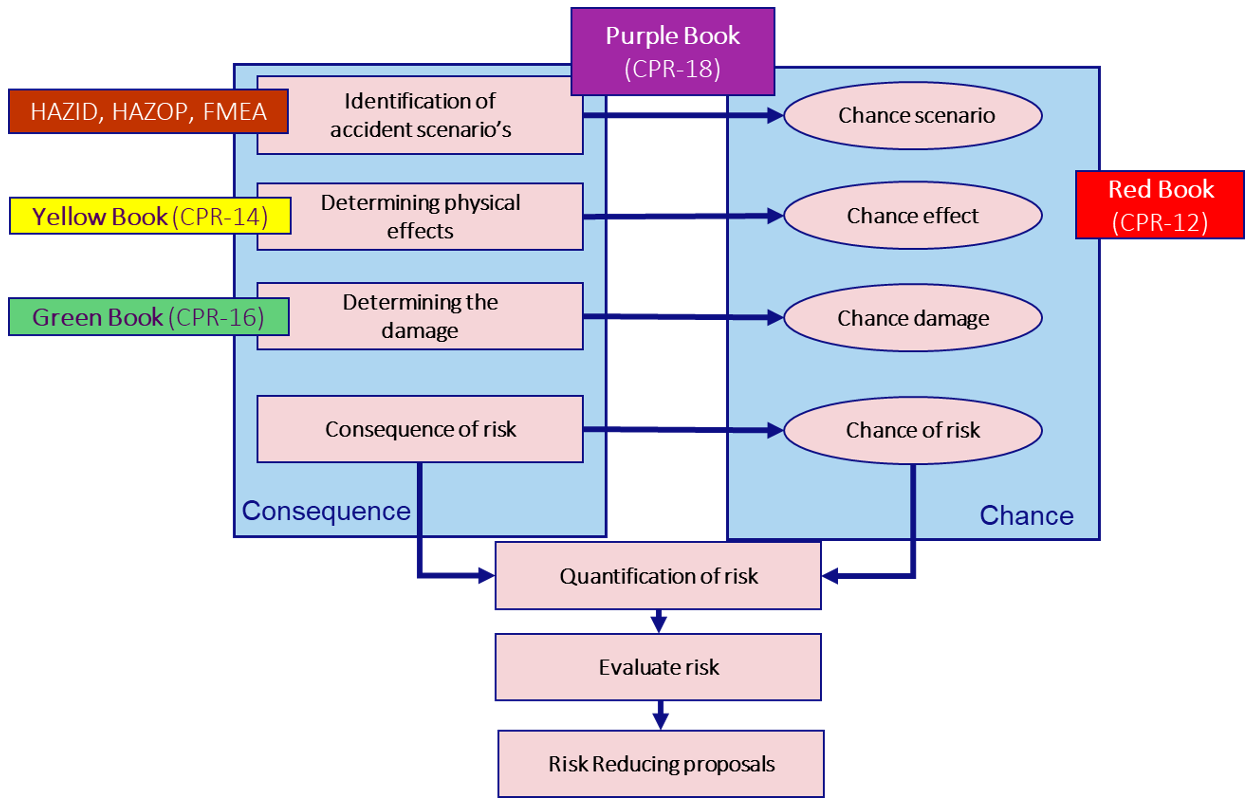

That is why Quantitative Risk Assessments (QRAs) are performed; to evaluate whether the calculated risk is acceptable or not. Both consequence and risk modelling are necessary steps for the performance of a QRA.

The Coloured Books

The Coloured Books are widely regarded as the standard for consequence and risk analysis for industrial applications. They serve as how-to guidelines and are extensively used as a reference in the global safety community. Important parts of the research presented in the Coloured Books were performed by TNO, the Dutch organization for applied scientific research as commissioned by the Dutch governmental “Committee for the Prevention of Disasters” back in the 1990s.

The Coloured Books are also the base for Gexcon’s consequence and risk modelling software EFFECTS (Yellow Book and Green Book) and RISKCURVES (Purple Book). Although the coloured books were never updated after 2005, our software tools have been continuously developed over the years and now also incorporate various other approaches and methods. This way, we have ensured that they are kept up to date with the most recent research and scientific data.

The Coloured Books consist of the Yellow Book, the Green Book, the Red Book, and the Purple Book.

The Yellow Book

The Yellow Book presents different methods for calculating physical effects due to releases of hazardous materials. The Yellow Book classifies the different phenomena that can occur upon an accidental loss of containment scenario in:

- Outflow and spray release

- Pool evaporation

- Vapour cloud dispersion

- Vapour cloud explosion

- Heat flux from fires (such as jet fires, pool fires, flash fires, fireballs and BLEVEs)

- Rupture of vessels

The Yellow Book includes extensive information about the nature of all these phenomena, describes the empirical mathematical approach to simulate each of them, and includes information regarding the limitations and applications of these models.

The Green Book

The Green Book presents a series of methods for determining possible damage to people and objects resulting from the release of hazardous materials.

The Green Book explains how to translate consequence effects (that can be calculated with the models presented in the Yellow Book) to physical damage through a series of available models. Those models focus on calculating damage caused by heat radiation, explosion (overpressure) effects, or acute intoxication.

The Red Book

The Red Book presents methods for determining and processing probabilities.

The Red Book also introduces the reader to some theoretical background about probability theory, statistics, and methods for determining probabilities such as Fault Tree Analysis, Event Tree Analysis, Markov processes, FMEA, etc.

The Purple Book

The Purple Book is a straightforward guideline on how to perform QRAs. It focuses on criteria like Individual Risk (Locational Risk) and Societal Risk as a way to quantify external safety, using generic failure frequencies for specified classes of process equipment. If you would like to know more about how to perform a QRA, please refer to the blog post “How to do a Quantitative Risk Assessment (QRA)”.

![Image Banner Source: This picture was courtesy of Chiltern Air Support as cited in [1]](https://gexcon-website.ams3.cdn.digitaloceanspaces.com/Blog/_thumb_460x345/60815/Picture-0.webp)